Crankshaft Grinding Service & Polishing

Are you looking for high-quality crankshaft grinding or polishing? John’s Grinding and Machine handles everything from small engines to industrial equipment.

With over two decades of machining experience, we have the expertise, technology, and precision to ensure the longevity of your engine.

Keep reading to learn more about our process and how we can help you with your crankshaft needs!

Our Crankshaft Machining Process

You won’t find any shop with more attention to detail and care for your engine than us! Here’s a brief overview of our crankshaft grinder process:

First, we visually inspect the shaft, looking for any apparent defects and indications. We also check the overall appearance of the thrust and seal surfaces.

After removing all Allen head plugs and lightening hole core plugs, we then meticulously clean the crankshaft, ensuring all oil passages are thoroughly cleared.

A micrometer is then used to measure the taper and out-of-round deviations of the main and rod journals. The thrust surfaces are inspected and measured with the same care.

Next, we conduct a crucial Non-Destructive Testing (NDT) to verify there are no “indications.” Indications can sometimes be a crack or anomaly. This step is a key part of our quality control process.

After NDT is performed, we check the run out and straighten the crank if necessary.

At this point, we check the Rockwell Hardness of the main and rod journals. Following that, the stone is dressed with a proper radius.

Then, the crank is loaded into the grinder, and we grind the rod and main journals. We also chamfer oil holes, polish the crankshaft, and recheck the Rockwell hardness.

NDT testing is again done to verify that there are no indications or anomalies after grinding and polishing. Lastly, the crank is thoroughly cleaned and bagged with paperwork.

Video: See Our Crankshaft Work In Action!

In this video, John has just set up the shaft to grind two of the rod journals for a 3406 CAT.

Benefits

- Cost efficient: New crankshafts are expensive! Repairing yours will save thousands.

- Retain your original crankshaft, so you don’t risk inferior quality and material strength.

- Quick turnaround time

- Frees up friction

- Reduces bearing speed

Why Choose John’s Crankshaft Grinding & Polishing?

A personal note from John Phillips, Owner of Phillips Racecraft and John’s Grinding & Machine:

I feel incredibly fortunate to have received training from Kenny Ewton, known as “Ken the Crank.”

Ken was previously a partner with Larry Arnold at Kryptonite Crankshafts. He also managed the crankshaft division at Hillcrest Camshaft Service, an awesome crankshaft and camshaft grinding service based in Arkansas.

Under Ken’s guidance, I have mastered the tips, tricks, and procedures to ensure your crankshaft will last and optimally perform for years to come.

I’ve been doing this for a long time, too – 25 years, to be exact, so you know you’re in good hands!

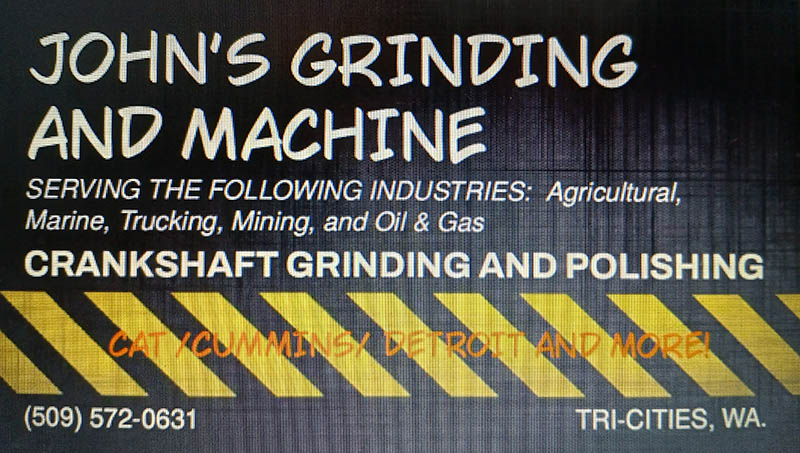

We Service The Following Industries & Engine Types

Industries served: Agriculture, Mining, Marine, Trucking, Oil and Gas

Engine types: all small engines (cars) and heavy equipment from CAT, Caterpillar, Cummins, Detroit, John Deere, Volvo, and many more.

Areas Served

Our commitment to excellence in crankshaft grinding, polishing, and machining makes us a top shop in the Tri-Cities area (Richland, Pasco, and Kennewick).

We also frequently work with clients from Seattle, Spokane, Yakima, Portland, and Boise. So, if you’re in these areas, too, feel free to give us a call.

But we’re happy to work with anyone from anywhere (as long as you’re willing to bring your crankshaft from your engine to us).

Contact John’s Machine Shop

We look forward to helping you with your crankshaft grinding and polishing needs! (We’re also happy to assist with any repair work.)

Please click on the button below for a free custom quote for your project. Or you can also call us today at 509-572-0631.

Our Grinding Place

Our crankshaft location is 1990 Saint St, Suite B, Richland, WA (by appointment only). Please call John or click the button above to schedule a time and date that works for you.

Be sure to check out our complete list of shop services for more ways we can help!